Cohesive particles in a powder can form larger particles with material handling. This process can be intentional as in a granulation process or can be unintentional as in caking during storage. Either way a powder's quality is affected by the formation of these larger particles.

The REVOLUTION Granulation Test can be used to study powders that exhibit particle size change during mixing, blending, transportation, production processing and/or storage.

|

Initial Sample |

Sample after Granulation |

When a cohesive powder is placed in a rotating drum, the continual angular velocity can cause the powder's particles to join together forming large particles. The flow properties of this granulated powder will improve with the formation of larger particles. The granulation analysis will measure the percentage of change in the avalanche power from the initial powder state to the granulated state. Once your powder has granulated, the REVOLUTION Granulation Test can also test the strength of the granules by increasing the drum rotation speed to force high velocity collisions between the granules. These collisions could cause the newly formed granules to break up. The granulation software compares the results of the powder's properties after granulation and after the increase in velocity to see if the powder remained in a granular state.

Appropriate powders for the REVOLUTION Granulation test include: food powders, cosmetics, pharmaceuticals, and other powders with granulation potential.

The REVOLUTION Granulation Test has five process steps: initial analysis, agglomeration, agglomeration analysis, de-agglomeration, and de-agglomeration analysis. These steps are discussed below.

|

Initial Step The initial step will indicate the powder's initial product characteristics by measuring the statistical analysis described below. These initial parameters as seen in Figure A will be used as a comparison to the agglomeration and de-agglomeration analysis steps. The software can measure the powder's ability to granulate during storage by performing the initial granulation analysis, storing the powder for a specified amount of time and continuing the agglomeration and de-agglomeration steps at a future date. |

Initial Sample |

|

Granulation Step The agglomeration step can be performed within the REVOLUTION Powder Analyzer or in the manufacturing process. Within the instrument, the powder is rotated at a fixed velocity for a specified amount of time to allow the particles to granulate. The rotation speed and time of rotation of the agglomeration process are set based on the process parameters. In the manufacturing process, a powder sample is taken after the granulation process or material handling. The new sample is loaded into the test drum. |

Granulation |

|

Granulation Analysis The agglomeration analysis indicates if your powder granulated or clumped in the agglomeration step, whether within the instrument or in your manufacturing process. The analysis is completed by determining the percentage of change in the statistical analysis between the initial stage and the agglomeration stage. |

Granulation Analysis |

|

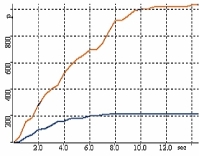

In Figure A, the analysis shows a reduction in the powder's avalanche power and time during the agglomeration stage. This change in power and time indicates that clumps are being formed during the agglomeration step. The formulation of granules allow the powder to avalanche more frequently and flow more freely. As a result of this analysis, the conclusion is made that this powder is granulating in the agglomeration process step.

|

Figure A - Cumulative Avalanche Spectrum - Initial Sample Granulated Sample |

|

De-Agglomeration Step The de-agglomeration step can be performed within REVOLUTION Powder Analyzer or in the manufacturing process. On the instrument, the powder is rotated at a high fixed velocity for a set time to cause particle collisions. The rotation speed and time of rotation of the de-agglomeration process are set based on the process parameters. In the manufacturing process, a new powder sample is taken after de-agglomeration process or material handling. The new sample is loaded into the test drum. |

De-agglomeration |

|

De-Agglomeration Analysis The de-agglomeration analysis will indicate if the clumps (or granules) formed during the agglomeration step break up with an increased rotation speed. The analysis is completed by determining the percentage of change in the statistical parameters from the agglomeration analysis to the de-agglomeration analysis. |

De-agglomeration Analysis |

|

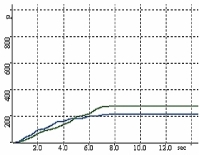

In Figure B, the analysis shows a slight increase in the powder's avalanche power and time. Based on this analysis, the conclusion is made that most of the granules formed during the agglomeration process have not broken up into smaller particles with the increased rotation speed in the de-agglomeration stage.

|

Figure B -Cumulative Avalanche Spectrum Granulated Sample De-agglomerated Sample |

|

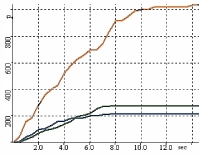

In addition, a comparison is made between the results of the de-agglomeration stage to the initial stage to see if the powder returns to its initial powder's characteristics. In Figure C, the analysis shows the difference in the avalanche power and time between the powder's initial analysis, agglomeration analysis and the de-agglomeration analysis. Therefore, the conclusion is made that the powder did not return to its initial powder characteristics.

|

Figure C Cumulative Avalanche Spectrum Initial Sample Granulated Sample De-Agglomerated Sample |

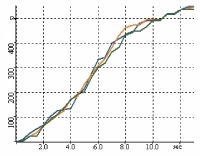

Figures D and E show the difference between the sample results when a sample granulates and when no granulation occurs.

|

Figure D Cumulative Avalanche Spectrum Granulation |

Figure E Cumulative Avalanche Spectrum No Granulation |